Laser Ablation Paint Removal

World s only laser ablation system in production use on flight critical surfaces.

Laser ablation paint removal. Laser paint removal laser paint removal is a process through which a paint layer is removed from a surface without damaging the substrate. Other applications for laser ablation. A list of all other applicable processes for the cleantech. Our systems replace current methods of chemical abrasive blast and high pressure water blast that generate hazardous waste and are difficult to control creating unsafe work environments.

It s also known as laser coating removal and de coating. P laser uk offers laser beam cleaning technology for gentle and efficient surface treatment of industrial components both metal and ceramic. The laser beam is pulsed onto the part with a precise energy density. At 52 feet tall over 100 000 pounds and with a reach of 85 feet lr systems laser ablation mobile robot is one of the largest if not the largest mobile robots in the world.

Laser cleaning systems combine power and versatility. This is done through a process called laser ablation which removes almost anything that absorbs laser light. Innovative laser ablation technology for industrial surface treatment cleaning and paint removal applications. Any application that requires the removal of contaminants from a substrate.

Rust or oils from automotive parts paint from aircraft heavy duty coatings from tanks ships or even. The most popular and proven applications of the cleantech handheld laser cleaning systems are parts cleaning paint removal rust removal and surface conditioning. Surclean manufactures laser coating removal and surface preparation equipment that is precise safe and clean. Our laser technology clears away contaminants and coatings on any type of surface without affecting the integrity of the surface.

The handheld laser cleaners process a wide range of materials with special attention to highly reflective metals. As the paint is vaporized the. If you are looking for a cleaning process that requires no abrasive consumables no toxic chemicals no mess to clean up afterwards no damage to metal or ceramic parts then we can provide such a system. This summer the company based in the netherlands plans to install a laser coating removal robot lcr at the maintenance facility of a yet to be announced large airline figure 1.

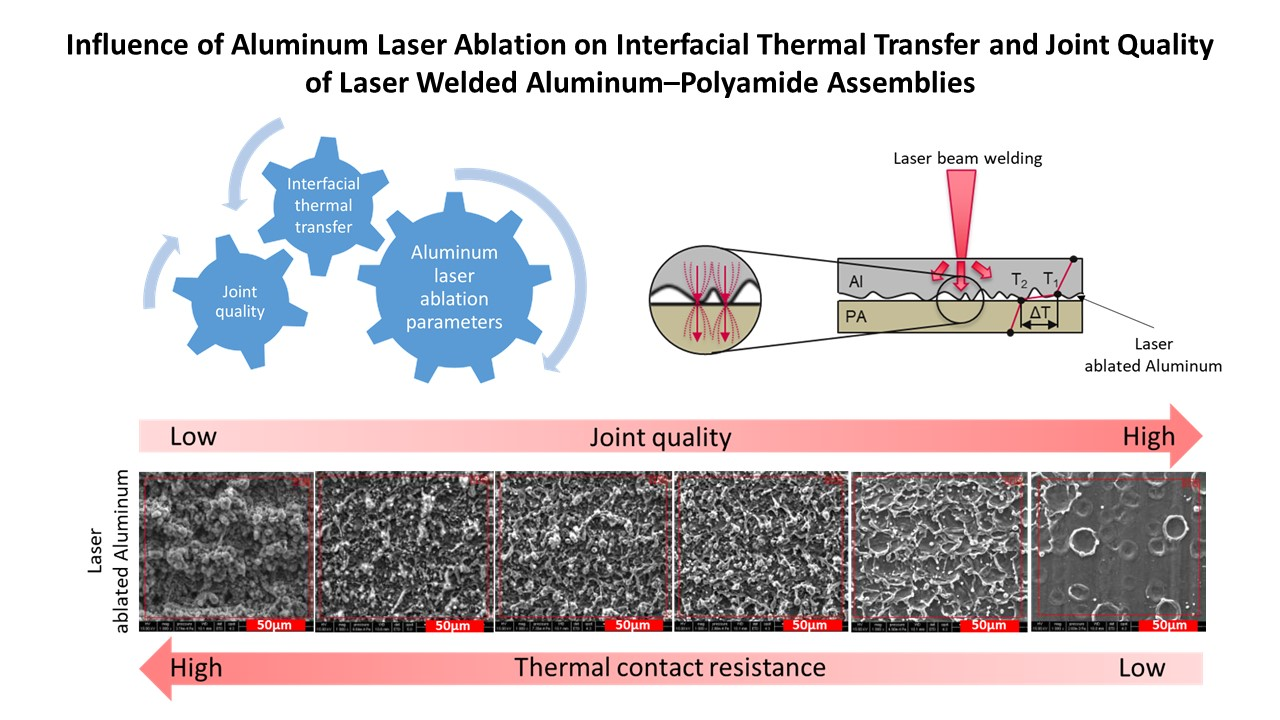

It is higher than the paint ablation threshold but lower than the substrate ablation threshold. Precise stripping by layer. Lasertronics has perfected unique scanning and computerized control technologies that make laser ablation a practical alternative to blasting abrasives and solvents for removing coatings of any kind with no risk of damaging any substrate. 16x faster than chemicals.