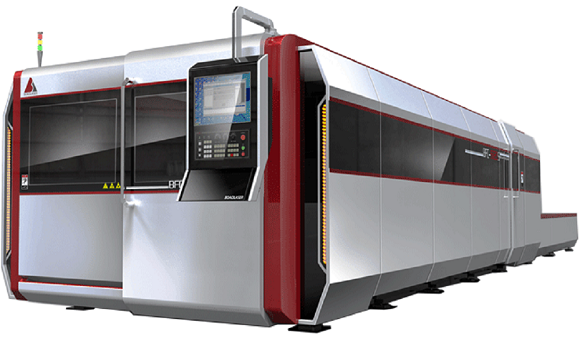

Laser Cutter For Silicon Wafer

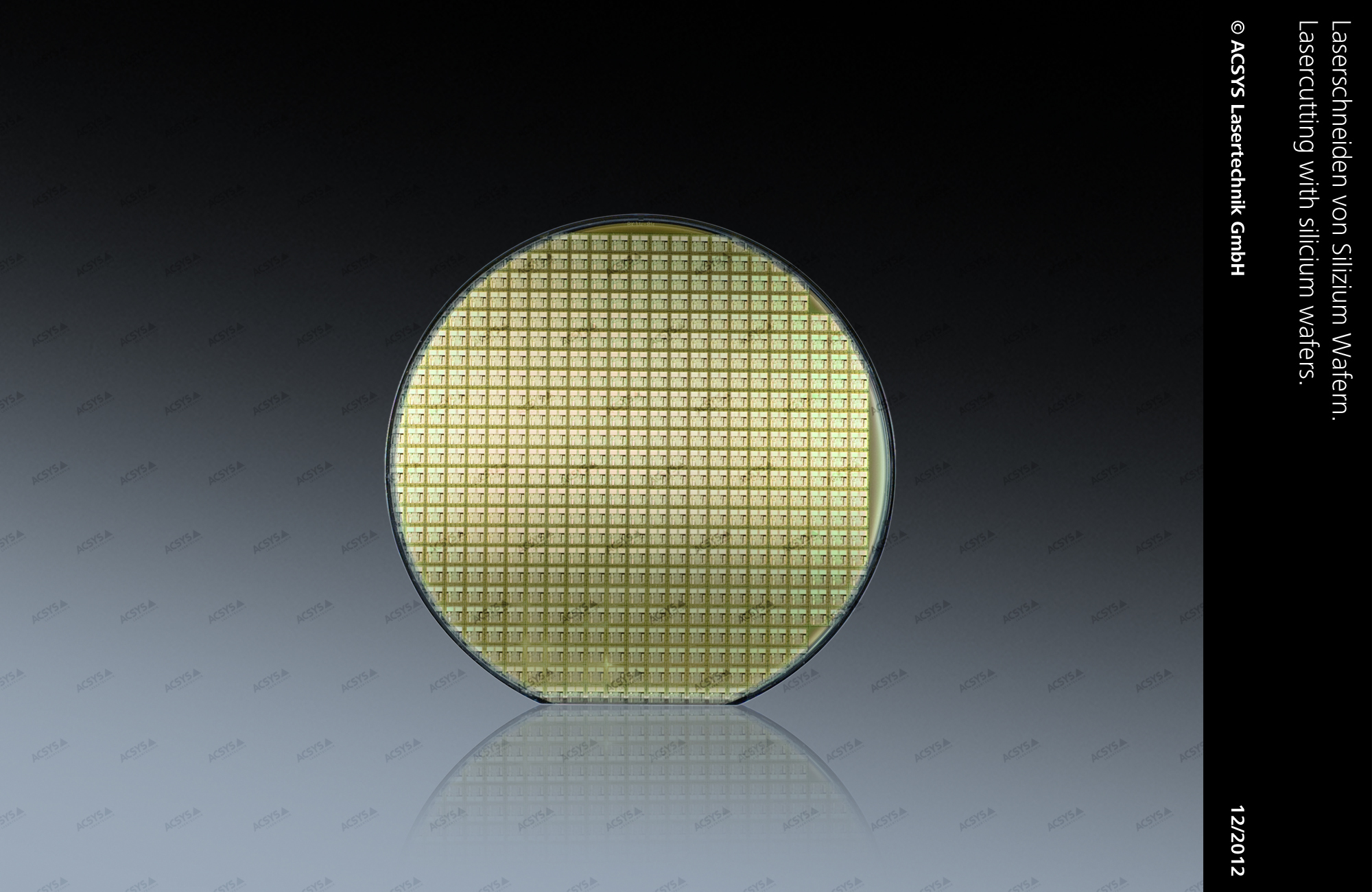

Solutions are available for machining smaller diameter wafers from larger ones solar cell downsizing or silicon stencil cutting.

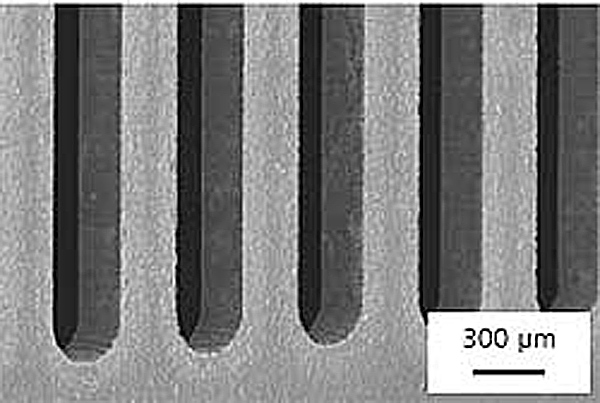

Laser cutter for silicon wafer. We tried cutting a silicon wafer with fabool laser mini 1 6w and 3 5w model. For silicon wafers less than 100 μm thick laser ablation offers an alternative to the blade technique which is too powerful for the delicate thin wafers. Laser cutting of silicon wafers is possible in all sizes and thicknesses with feature sizes as small as 20 microns. Demonstration of cutting features into 1 5 mm thick silicon wafers using a laser micromachining system equipped with a qcw laser.

Traditionally silicon wafers have been cut with diamond saws occasionally using a scribe and break process which have the limitation that they can only cut straight lines and suffer from edge chipping and frequency doubled vanadate lasers which are both slow and expensive to operate as is the microjet process. This is usually followed by a mechanical breaking procedure to produce silicon rectangular tiles for subsequent operations he mechanical break will follow allowing the scribing line offering the least path of resistance. Due to the reflection it only made slight scratch and could not cut. The same system can be used to downsize larger silicon wafers for use in smaller format processing tools.

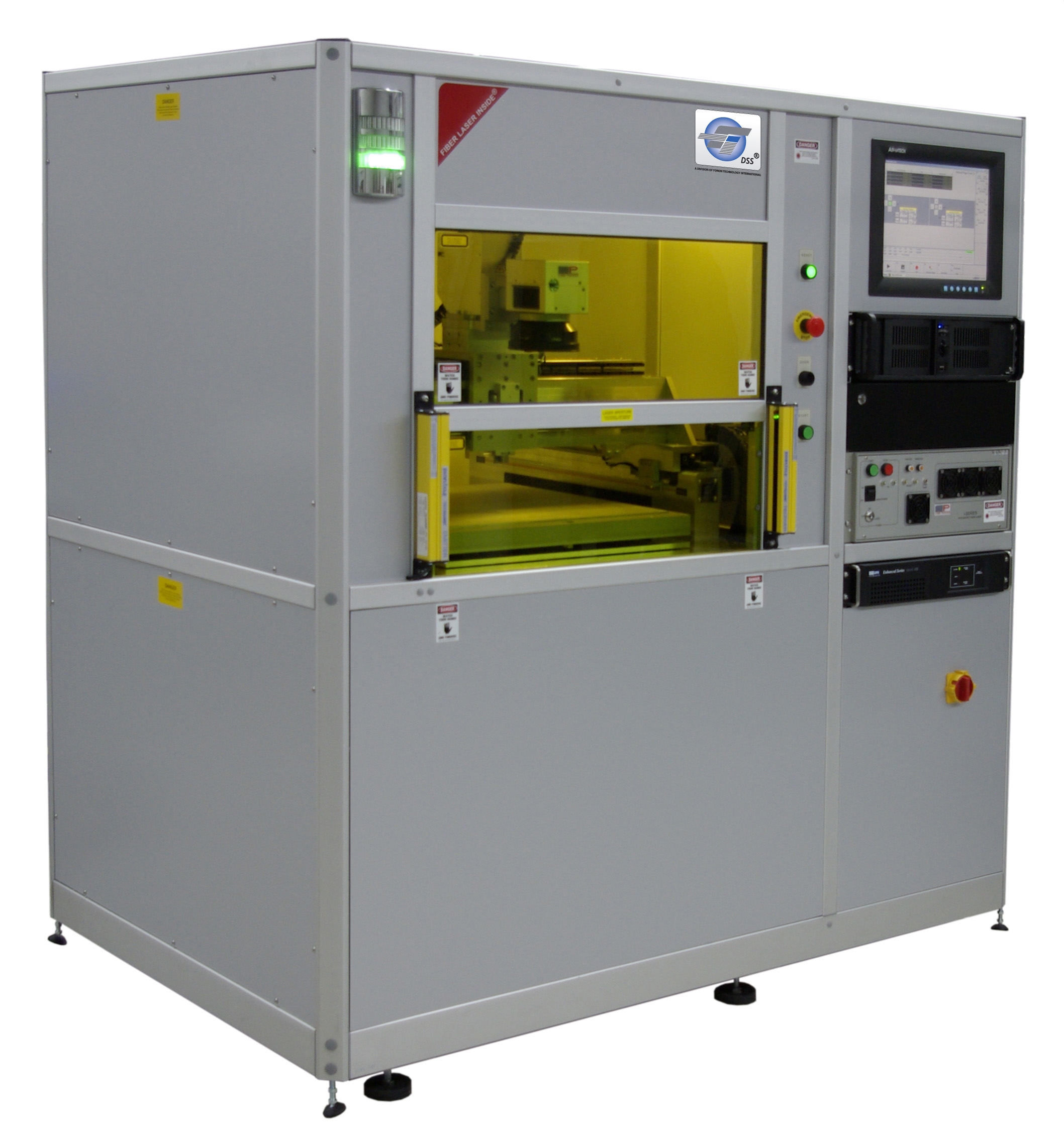

How is laser dicing silicon being processed. Material thickness up to 1mm. Laserod has a division that focuses on the building and integration of a full line of fiber laser micromachining equipment and a diode that can be used for laser dicing silicon wafer resistor trimming scribing substrates of silicon and alumina and cutting thin plastics and metals. In addition complex features such as channels and pockets and channels can be machined in silicon wafers.

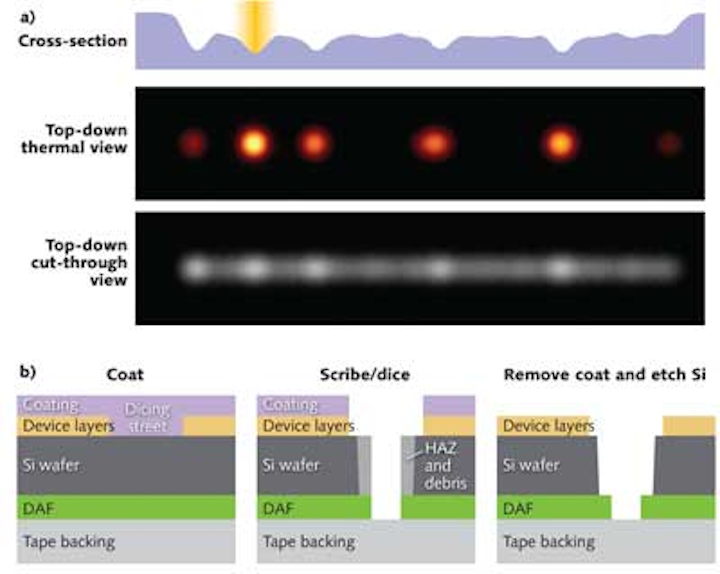

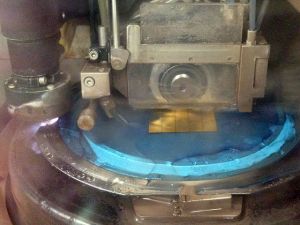

Dicing of silicon wafers may also be performed by a laser based technique the so called stealth dicing process. Sapphire silicon wafer cutter. The figure shows 700 µm wafer downsizing top view and side view. This lines introduces regions of weakness.

However laser ablation has its own problems. Cut features are round holes with no cracking or rough edges. It works as a two stage process in which defect regions are firstly introduced into the wafer by scanning the beam along intended cutting lines and secondly an underlying carrier membrane is expanded to induce fracture. Scribing causes partial cut lines on the wafer.