Laser Cutting Machine Time Calculator

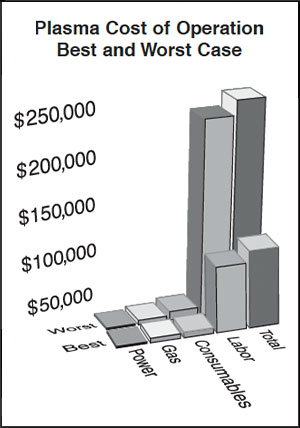

Attendance levels provide another opportunity for laser cutting machines to lower operating costs.

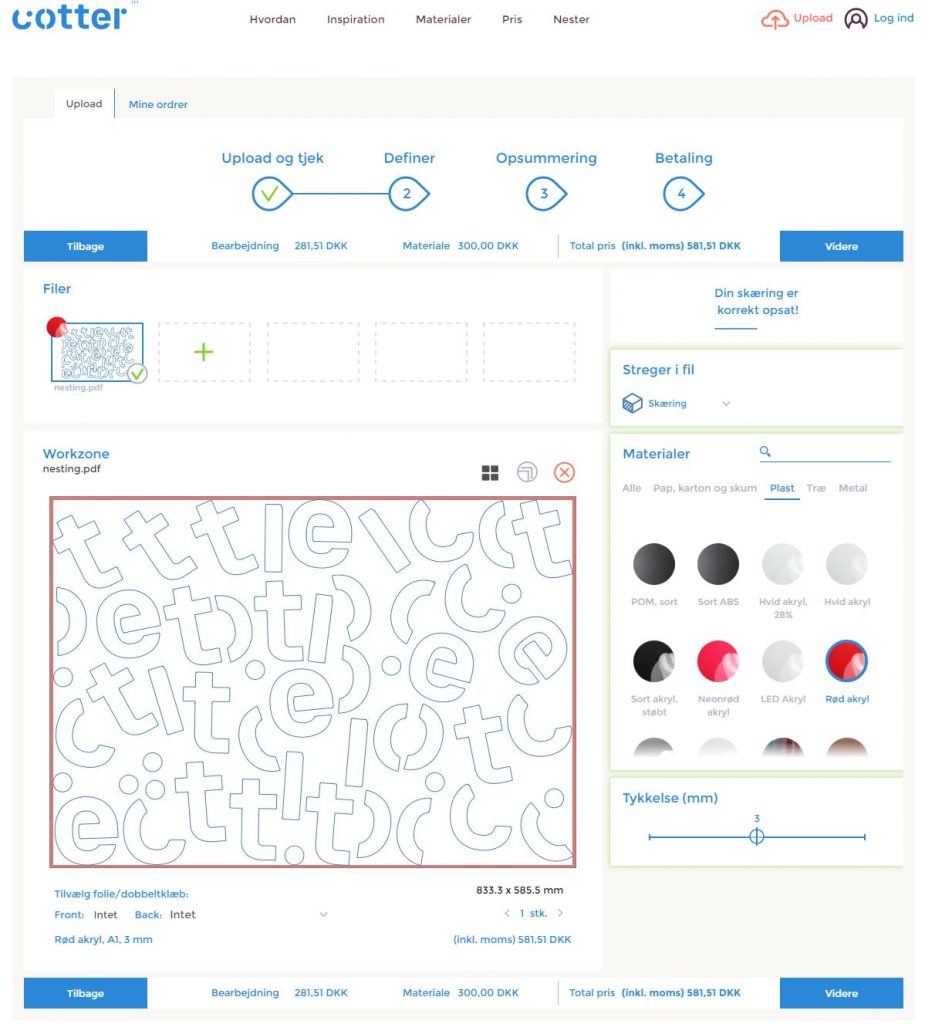

Laser cutting machine time calculator. Based on these inputs the cost model will calculate the appropriate cycle time and cost per piece. Then add in any non cutting time such as positioning and tool changes. To start your small business you need a minimum. It is not recommended to continuously process for a long time.

Cost and price calculator 12 1 business starting requirements. I want quick solution for that. The synrad laser processing calculator not only allows you to evaluate the feasibility of laser cutting applications with better predictive algorithms and visual feedback for various material types but it now includes the ability to evaluate simple laser marking applications. For example a drill or end mill cutting feeding 3 at 60 ipm 3 60 x 60 3 seconds.

Calculate the time for a tool by dividing the feed distance by the feedrate and multiply by 60. Costing from 500 6000 computer. Standard entrainment abrasive water jet cutting head 2 2 laser cutting there are two commonly used types of industrial cutting laser co2 and nd yag. Trutops calculate works out the processing times and costs that are to be expected for parts or entire assemblies.

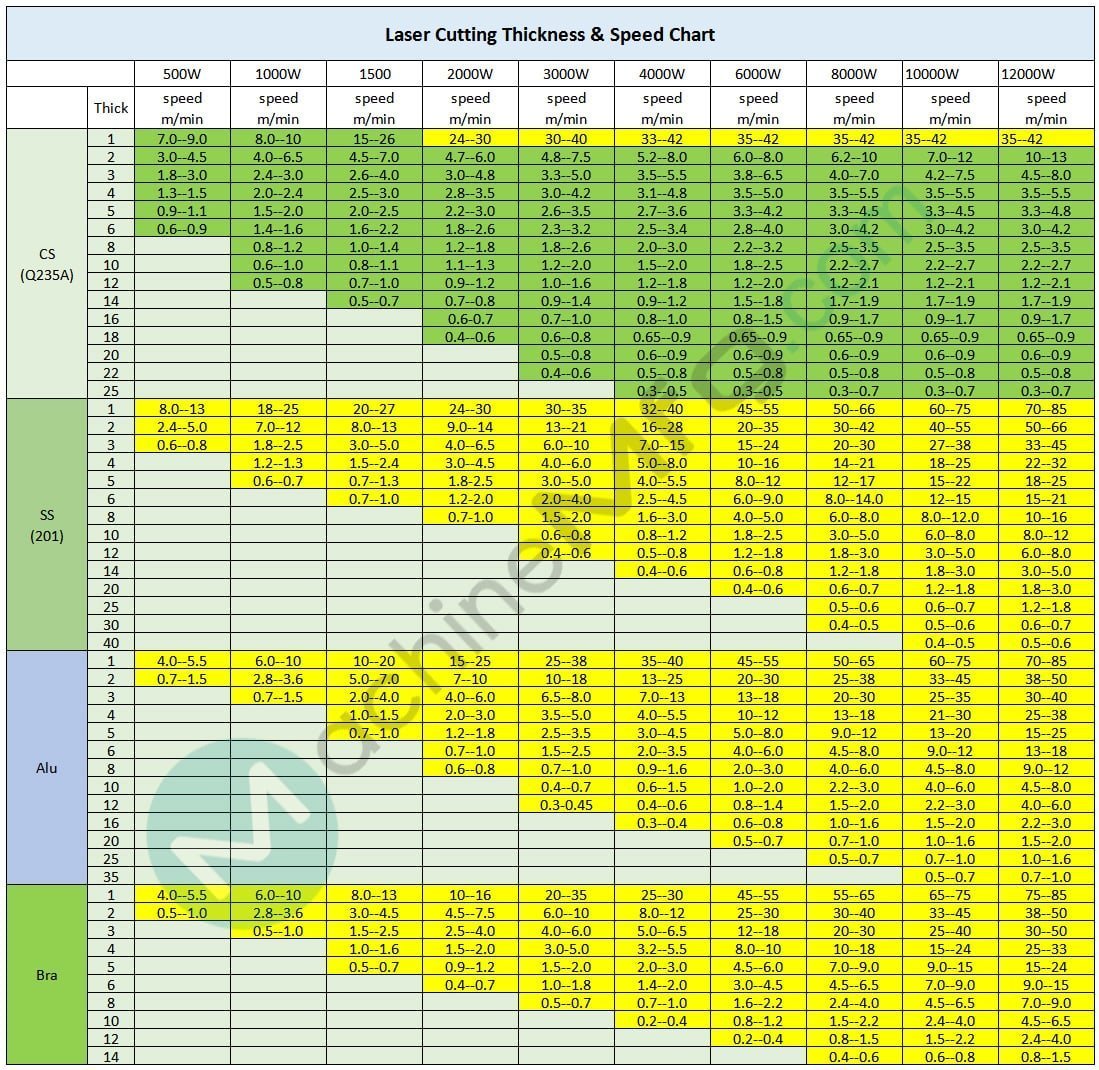

It uses the technology data of your trumpf punching punch laser laser or tube cutting machine in order to make the process of cost analysis and tender preparation easier for you. The costimator lasercut cost model will calculate the time and cost to lasercut a part with four input variables. To calculate your material cutting speed and waterjet pump pressure download the kmt 60 000psi 90 000psi cutting calculator on your computer. Presently i have calculate with length measuring tool and adding the different length.

I have to calculate the laser cutting length. These differ in that the wavelength of infrared light produced is 10 6 µm for co2 lasers and 1 06 µm for nd yag lasers. Material type and thickness cut distance and number of holes. Both these types of lasers cut by focusing a.

For the cutting of high anti corrosive materials such as copper and aluminum attention should be paid to adjusting the process. Mid level computer with windows 7 810 800 1500 vector designing software. Designer pro e wf 3 user. Laser cutting in the processing of the limit material is inefficient and the effect will be reduced cannot be continuous processing.

If anybody know the solution please help me.