Laser Cutting Mild Steel With Nitrogen

If the steel is thicker than 1 8 in cutting speed is similar for both nitrogen and oxygen.

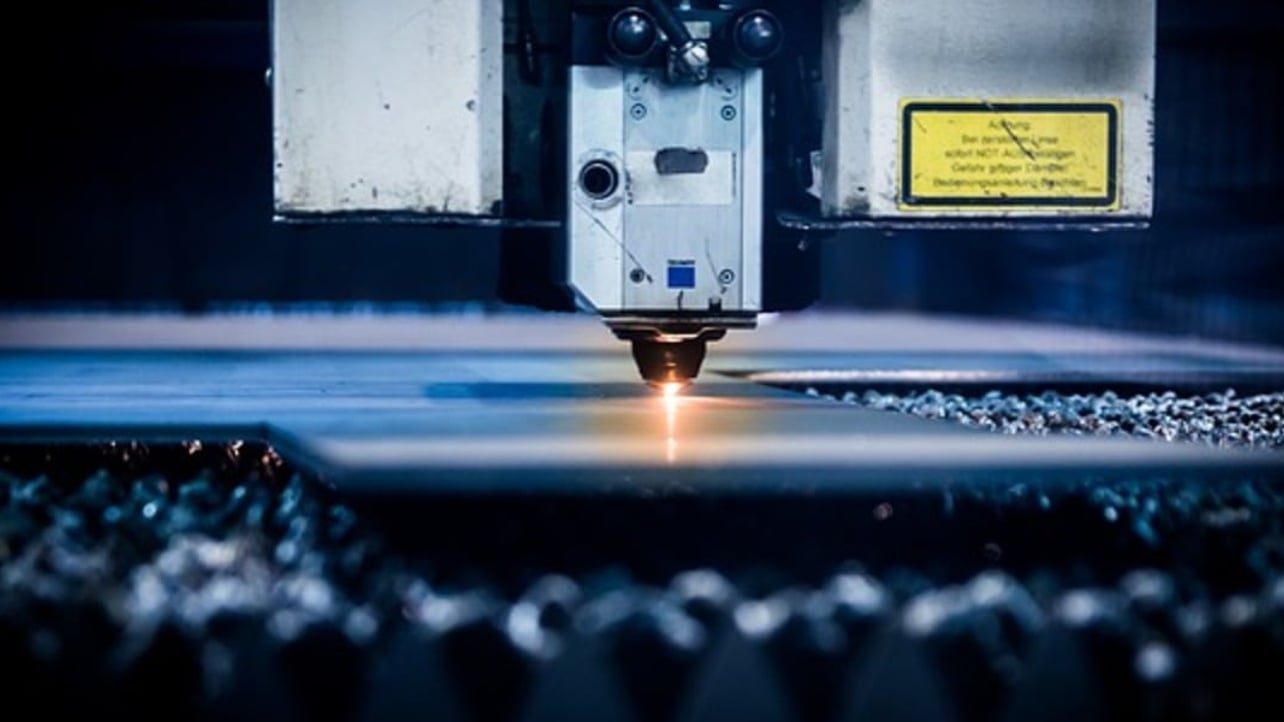

Laser cutting mild steel with nitrogen. When cutting thin gauge material there s not much need for additional speed. When carbon steel is cut with an oxygen assist gas the oxygen interacts with the hot metal to create an exothermic reaction which adds heat. Laser cutting mild steel with nitrogen. Cut the same sheet with oxygen assist gas and you get a rougher edge that needs clean up but thanks to the additional heat produced you can cut much faster.

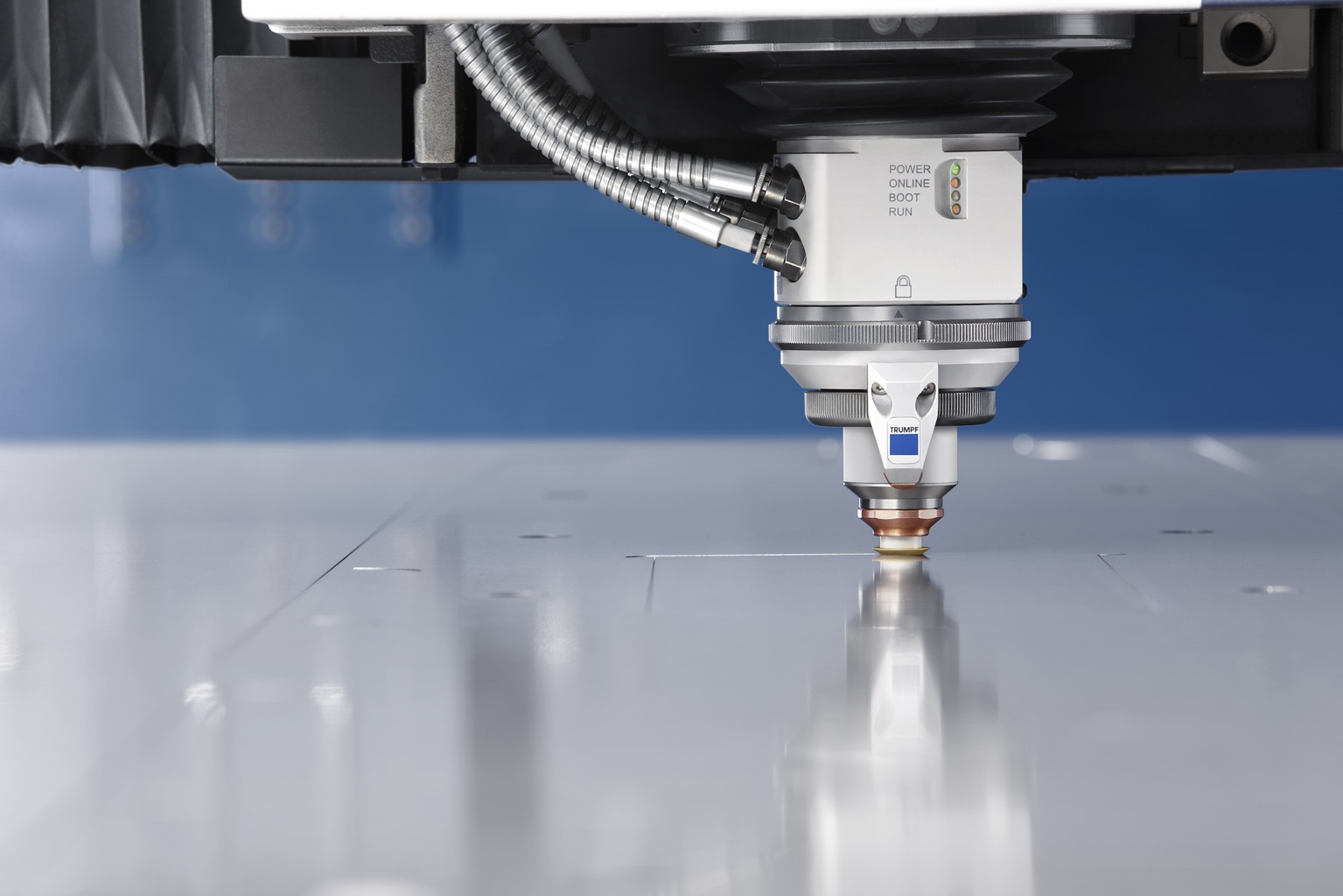

When using nitrogen an inert gas the cutting process relies solely on the beam s energy to melt the metal. Also if your cutting mild steel that has mill scale. Nitrogen or oxygen can be used as the assist gas. For mild steel and stainless steel thick sheets the ideal pressure lies in the region between 10 and 15 bar.

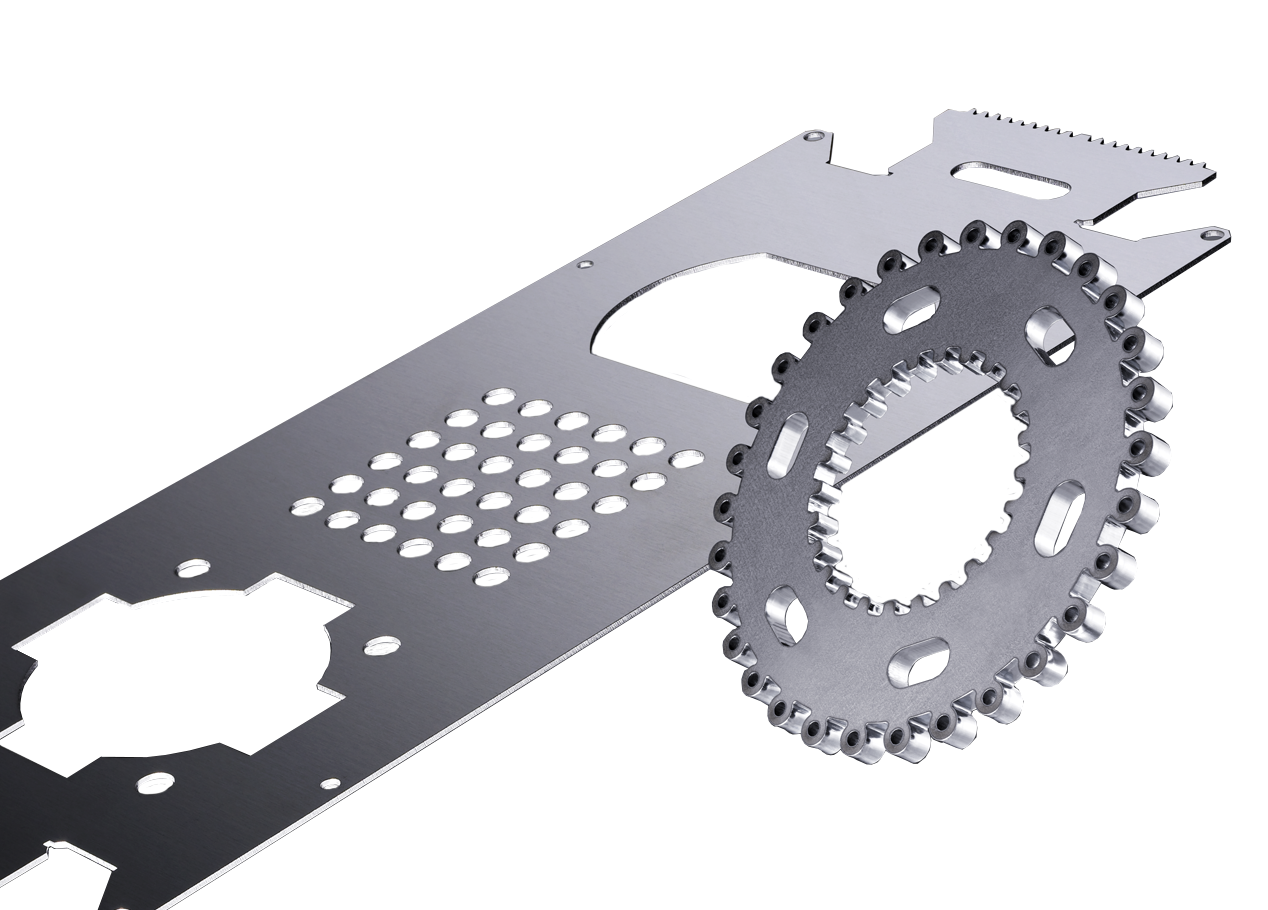

When cutting stainless steel or carbon steel with nitrogen the laser melts the steel and the nitrogen assist gas evacuates the molten material leaving an oxide free edge. However there are two choices when cutting mild steel. Factory cut chart settings. If you are cutting stainless steel or aluminium this is usually only cut with nitrogen or compressed air compressed air is typically used to laser cut material up to 2mm thick.

Speed at times is reduced for a clean cut by 20. Meeting your nitrogen purity challenges the nitrogen purity is important if a clean cut edge is required for example when cutting stainless steel or aluminium metals. The examples of the adjustments made will be similar for any co2 or fiber laser cutting mild steel with o2. The following show 12 6 and 3 2 mm 1 2 1 4 and 10ga mild steel cut with oxygen on a 2kw fiber laser and examples of the same part cut with 1 variable changed to show how it affected the cut quality.

Higher figures are possible with the most powerful lasers available. Cutting mild steel. Laser cut sheet with a nitrogen assist gas and you get a clean edge. Why laser cutting steel with nitrogen.

At our shop we nitrogen cut 7ga p o at speeds of about 70 80ipm on ext and around 60ipm on internal. I have a 160 w chinese laser that i would like to cut mainly 1 2 mm mild steel 1 2 mm stainless steel and up to 1 6 mm hr steel. Using nitrogen provides the most benefit when you are cutting very thin material. However if the laser cuts too fast turns a sharp corner or its focus is a little off you risk losing the cut and producing unusable parts.

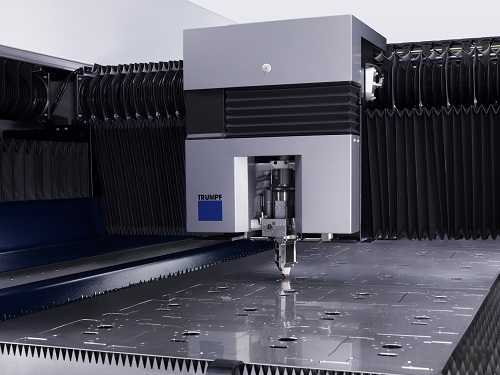

On amada fo3015 nt and 4020nt lasers.