Laser Cutting Time Calculation

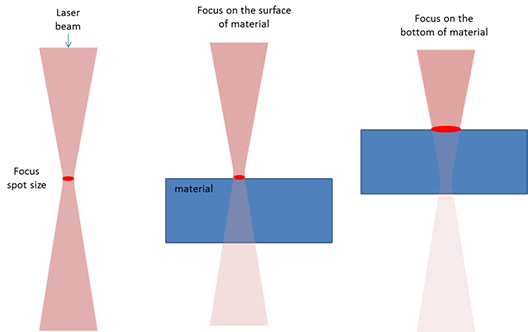

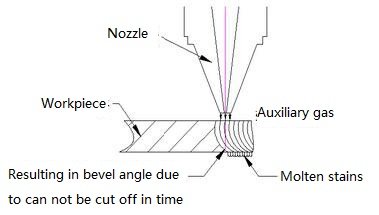

For the cutting of high anti corrosive materials such as copper and aluminum attention should be paid to adjusting the process.

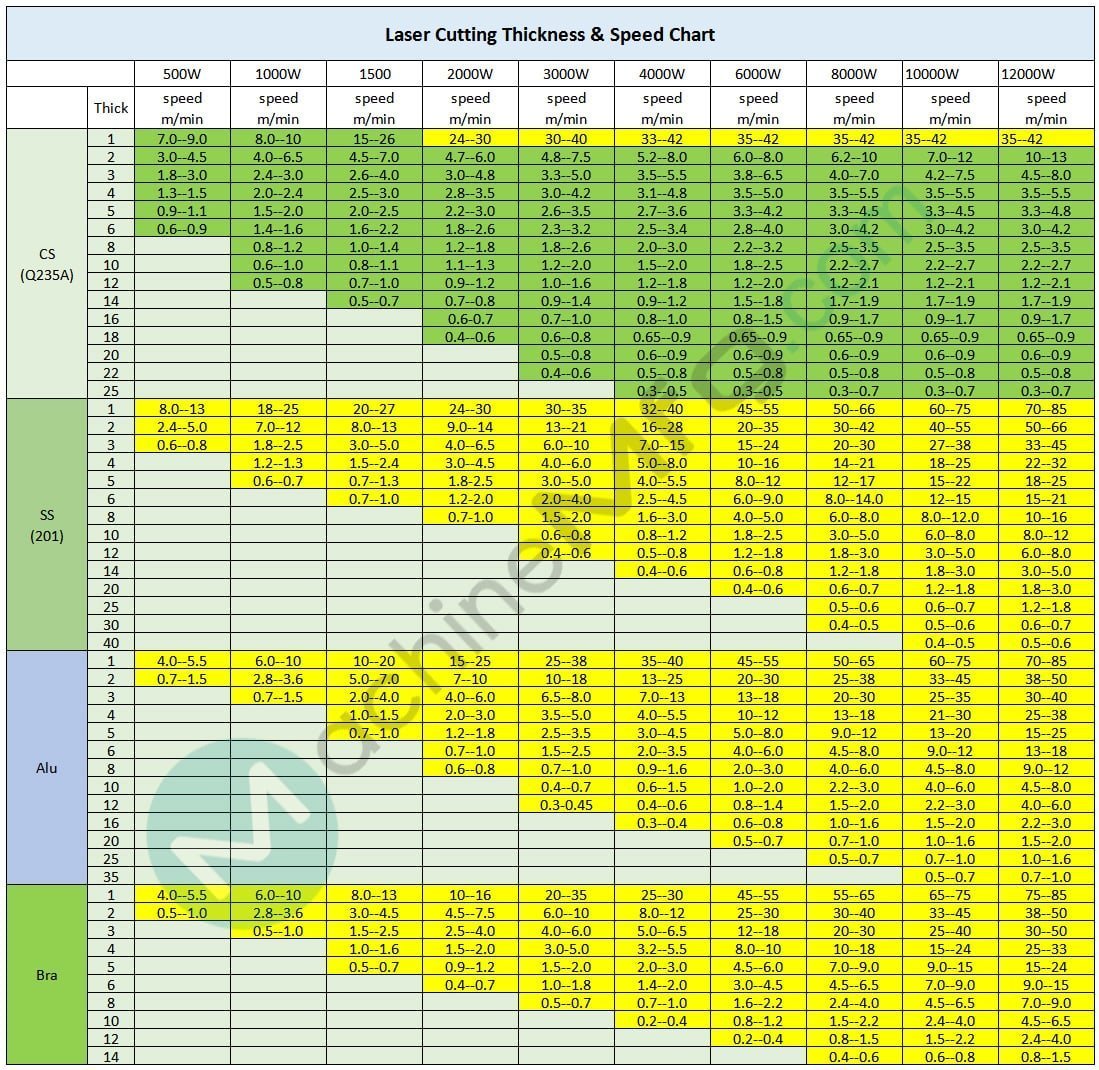

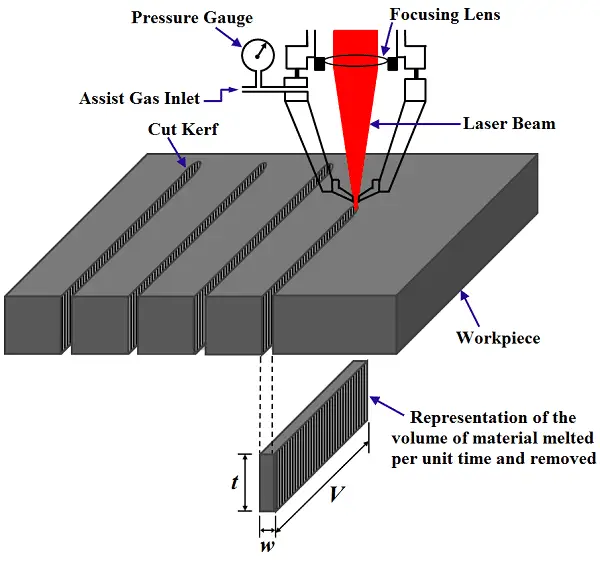

Laser cutting time calculation. And thinner while the advantage for punch plasma increases as material gets thicker. Laser process calculator the synrad laser processing calculator not only allows you to evaluate the feasibility of laser cutting applications with better predictive algorithms and visual feedback for various material types but it now includes the ability to evaluate simple laser marking applications. The time the job takes on a laser is dependent on the type of materials and the thickness of the materials being cut. Material type and thickness cut distance and number of holes.

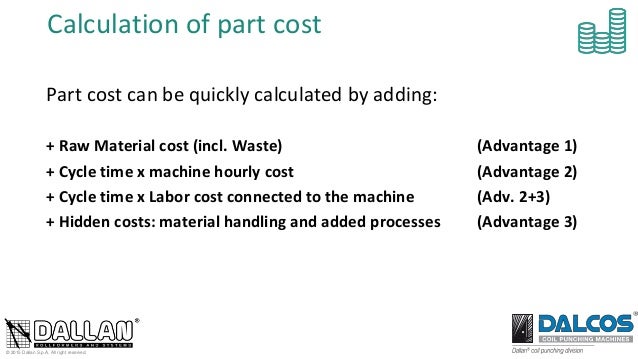

The costimator lasercut cost model will calculate the time and cost to lasercut a part with four input variables. Laser cutting in the processing of the limit material is inefficient and the effect will be reduced cannot be continuous processing. The length of all the cuts in the design can be used as a rough estimate of the cutting time consumed. To price laser cutting online we need to extract two pieces of info from uploaded design files.

These are only estimations and do not include material labor costs or setup fees. Laser cutting offers a lower cost for material about 12 ga. The area of a box surrounding the design called the bounding box is the amount of material needed. Laser cutting costs are calculated by the time a job takes on the laser.

Things to be aware of are the. 2 1 abrasive water jet cutting 6 2 2 laser cutting 8 2 3 oxyfuel cutting 10 2 4 plasma arc cutting 12 3 cut quality 16 3 1 iso 9013 16 3 2 other quality measurements 18 4 cut edge cracking 20 4 1 edge cracking 20 4 2 methods to avoid edge cracking 21 5 preheating experiments 24 5 1 results 26 5 2 analysis 26 6 interviews 27 7 calculation models. Based on these inputs the cost model will calculate the appropriate cycle time and cost per piece. Approximately 80 of the time while the program is running the laser is cutting this is the majority of the processing time.

In the heaviest thickness the punch plasma maintains a 40 percent cost advantage over laser cutting. In this scenario the precision plasma cutting process has the highest cost of the three processes.