Laser Cutting Working Principle

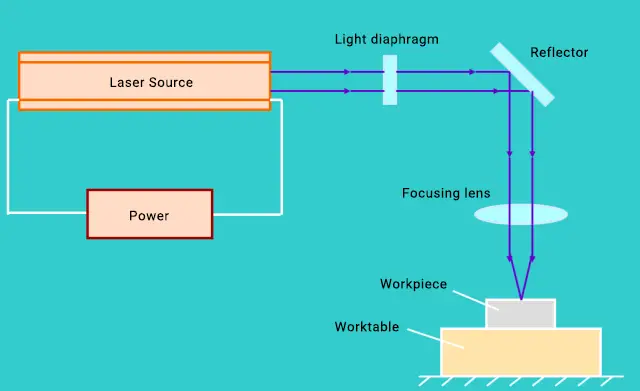

Spatial coherence allows a laser to be focused to a tight spot enabling applications such as laser cutting and lithography.

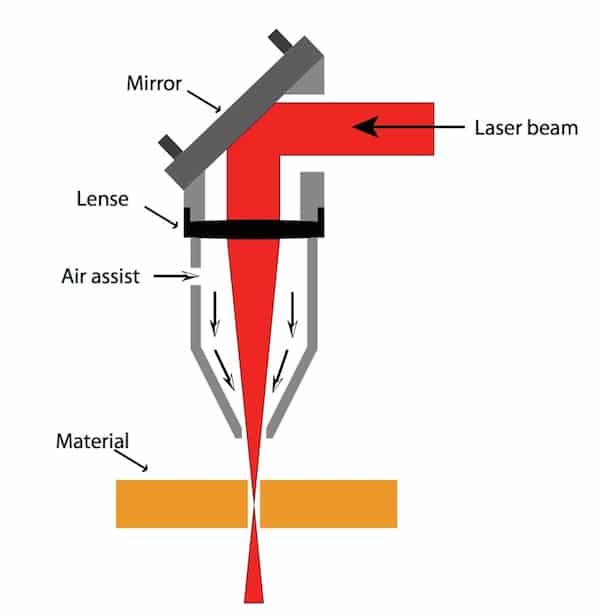

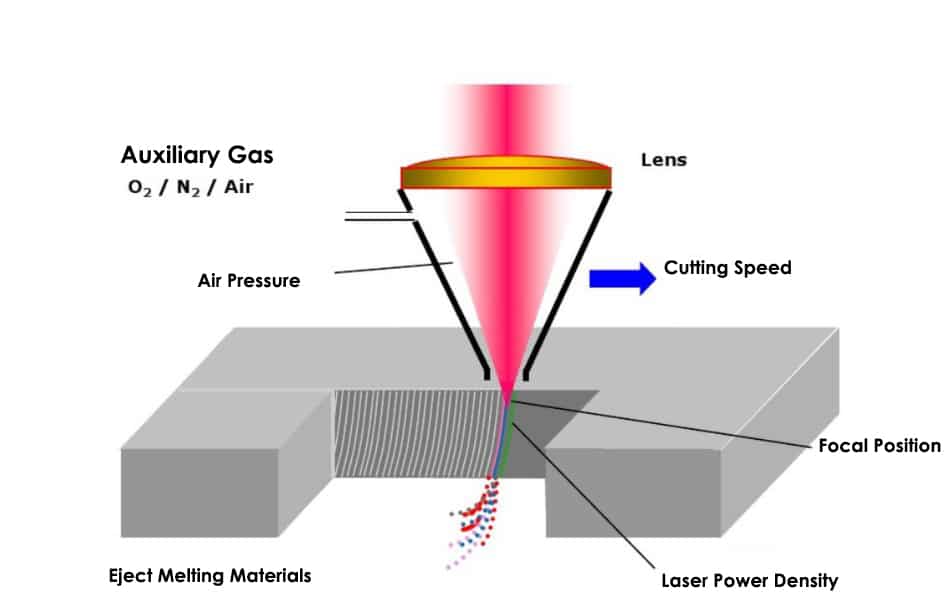

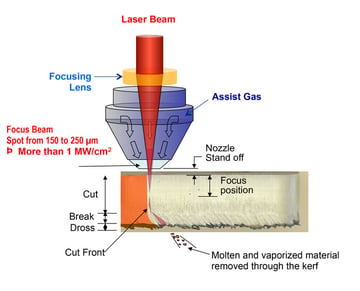

Laser cutting working principle. Yag and fiber lasers permit a controlled heat entry which is optimum for fine cutting. When cutting mild steel the heat of the laser beam is enough to start a typical oxy fuel burning process and the laser cutting gas will be pure oxygen just like an oxy fuel torch. Laser cutting works by directing the output of a high power laser most commonly through optics. The temperature of laser cutting exceed 11000 which would have made any material gasification therefore gasification also plays an important role in addition to the melting during laser cutting process.

Http www wissensfloater de arrangement physical requirements laser melt cutting laser flame cutting contours and bevel cuts punching of holes compari. In lasers photons are interacted in three ways with the atoms. Fiber laser cutting is a hot cutting method which makes use of the focused high power density laser beam as the main heat source to illuminate the workpiece cause the irradiation materials rapidly melting evaporation and ablation or reach the ignition point. Laser cutting uses the laser beam as the heat source for hot cutting its working principle is similar to laser welding.

The high peak performance of our laser permits a maximum cut depth of up to 10mm. The principle of laser cutting laser cutting is a thermal separation process. The laser optics and cnc computer numerical control are used to direct the material or the laser beam generated. A laser differs from other sources of light in that it emits light which is coherent.