Laser Drilling Micro Holes

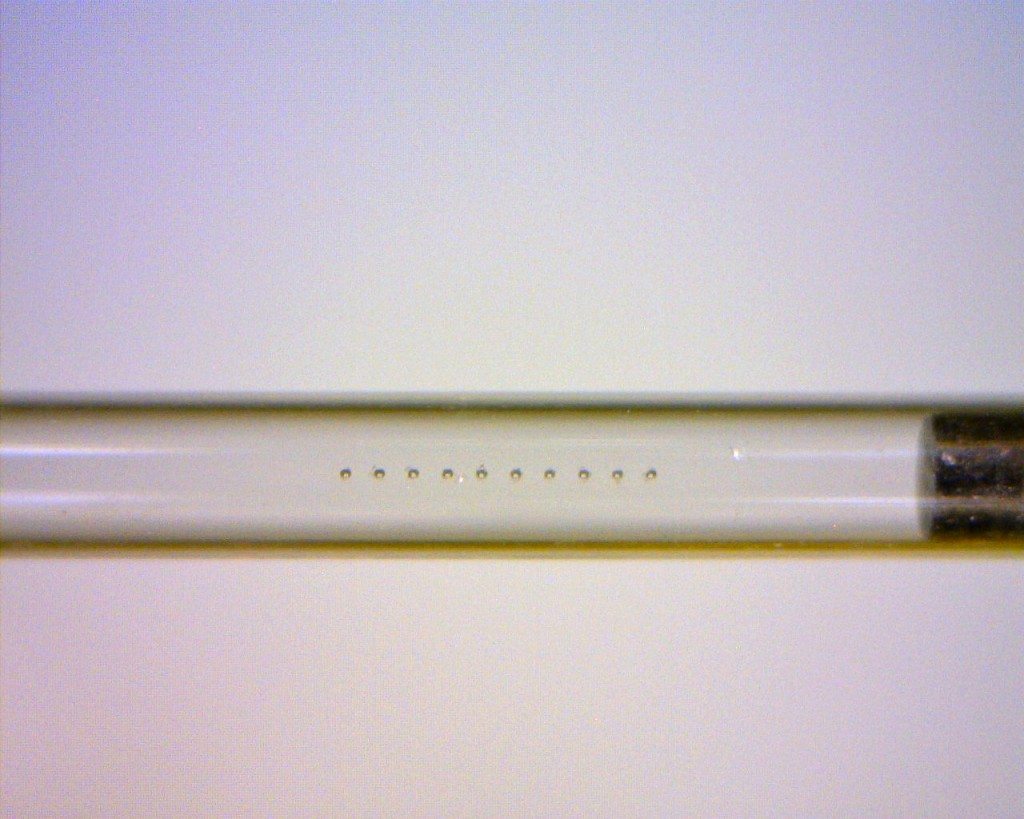

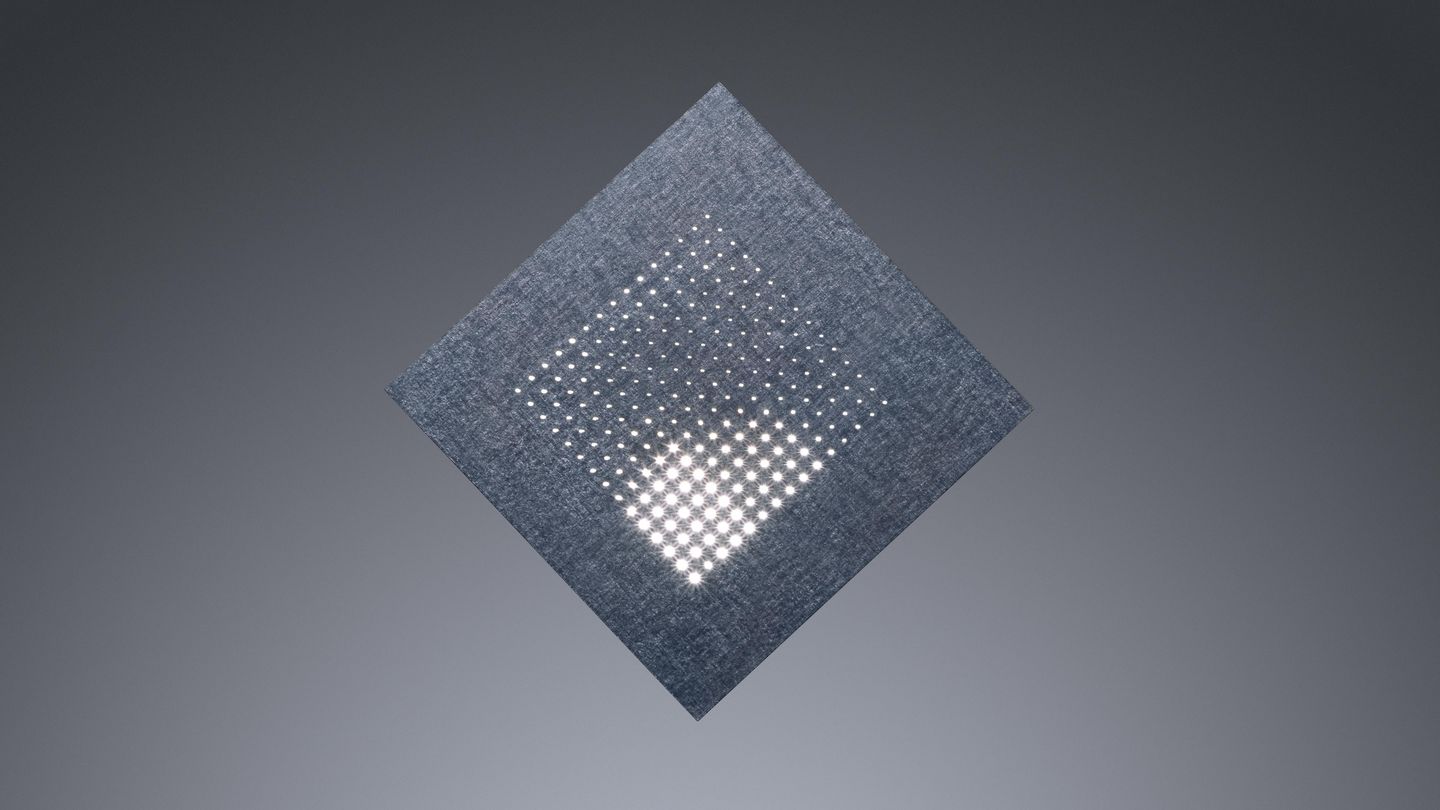

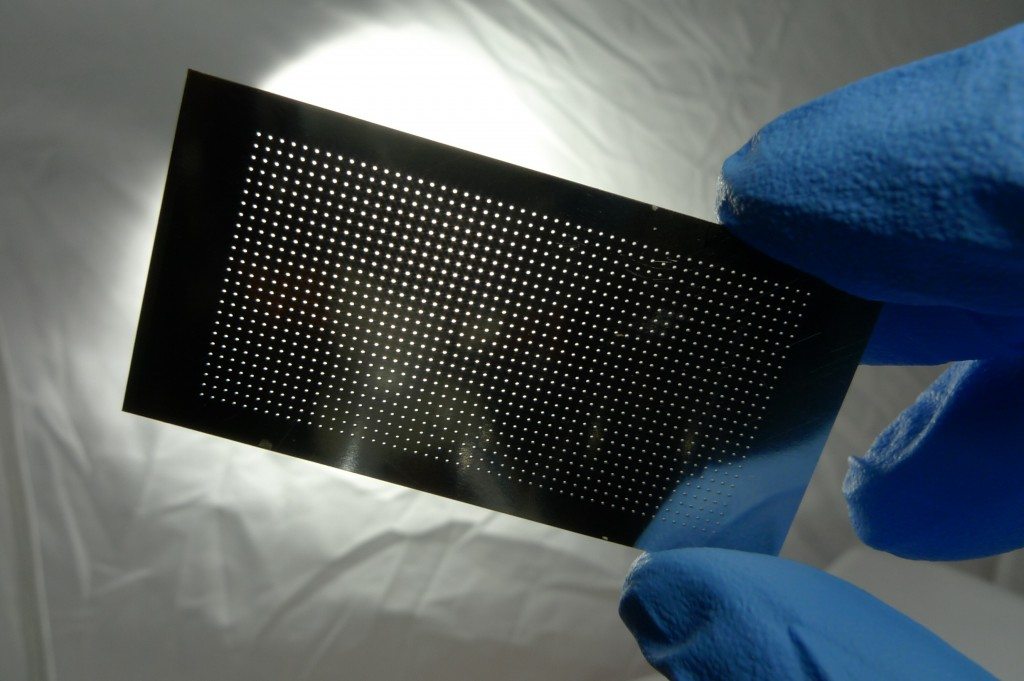

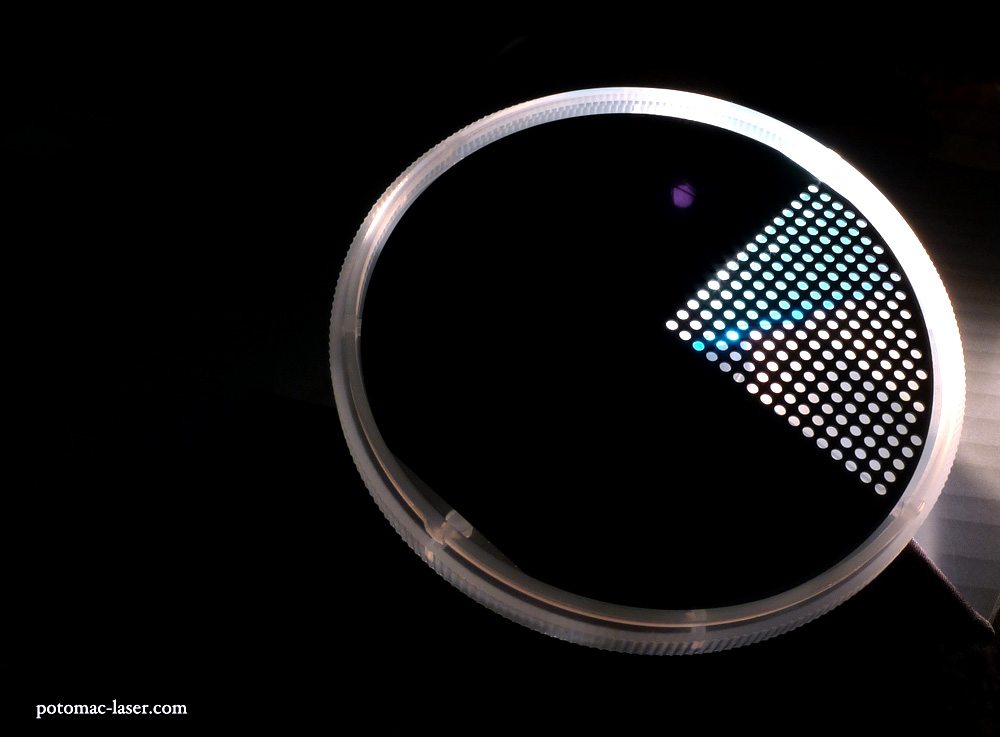

Drilling rates up to 1 000 holes per second are available.

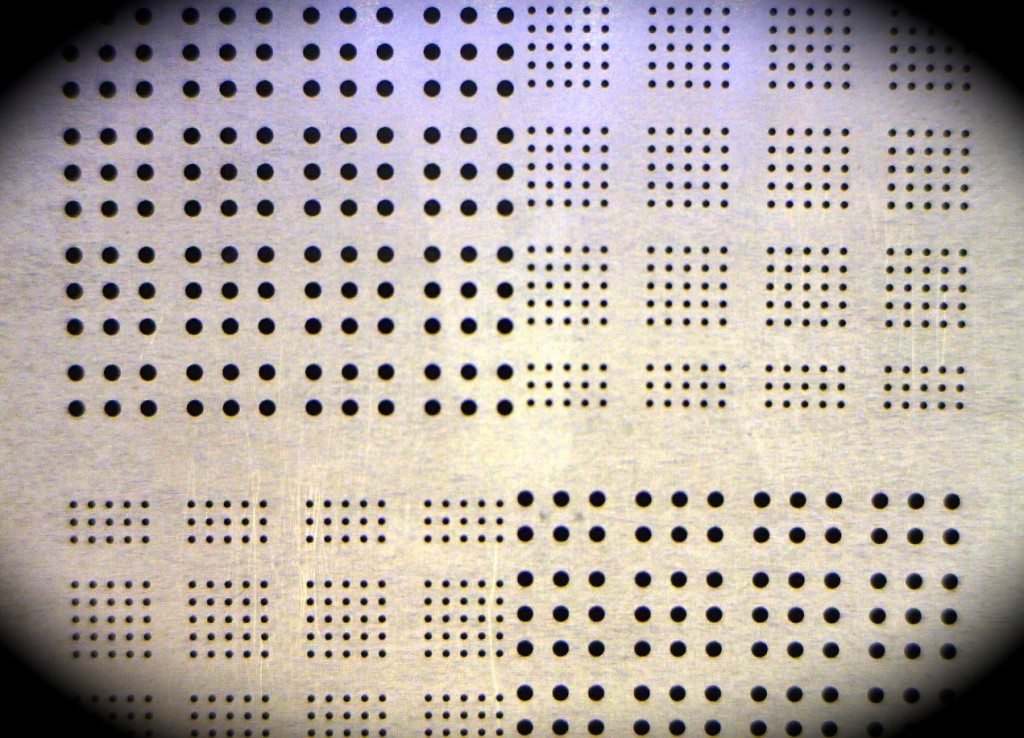

Laser drilling micro holes. Potomac is continually developing and adding new hole drilling processes to our facility. Round square rectangular oval etc. Laser drilling of micro holes is a key area for precision laser micromachining. Can be produced by varying the drilling technique.

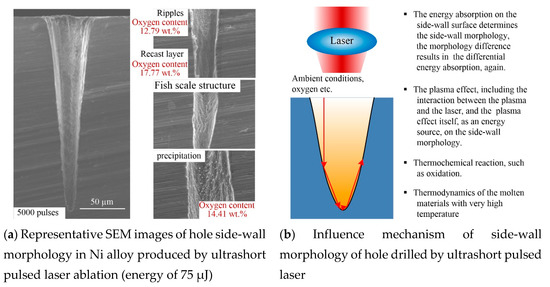

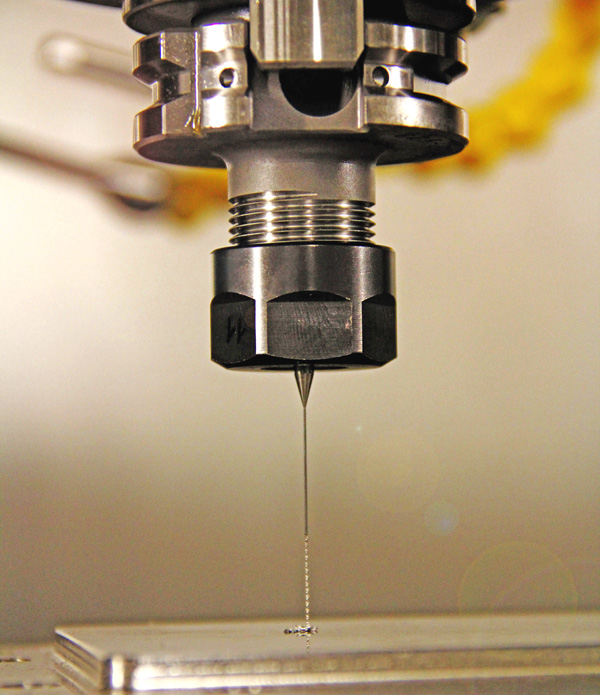

Laser micro drilling describes the use of a laser to drill precise orifices in various materials. Laser light works closely with you to match your unique micro hole drilling needs with the right solution for the most precise efficient results. And compared to other machine drilling techniques laser drilling. Request a free quote today.

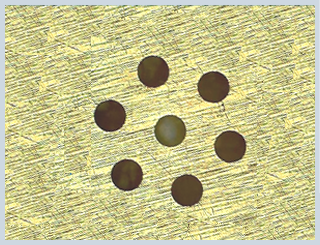

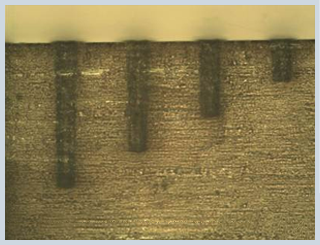

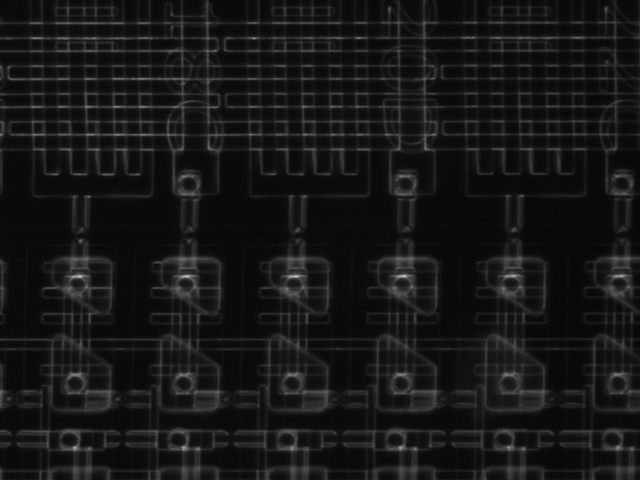

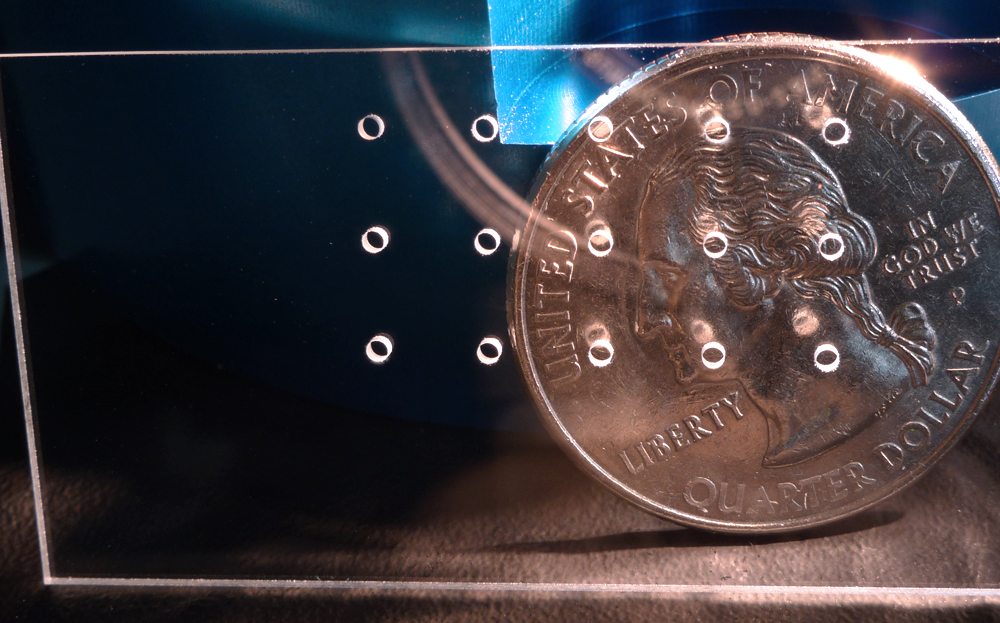

Compared to other drilling methods lasers offer superior speed and precision while lowering operating costs. Micro drilling applications include both through holes and blind holes and can demand vertical sidewalls or tapered sidewalls depending on the application. Critical items to consider when planning a hole drilling project include the diameter of the hole the thickness of the material the shape of the hole edge quality of hole desired taper of hole and center to center pitch of the holes. Laser micro hole drilling is widely applied to the creation of precisely controlled orifices for applications that demand a combination of small diameter exceptional quality and exacting tolerances.

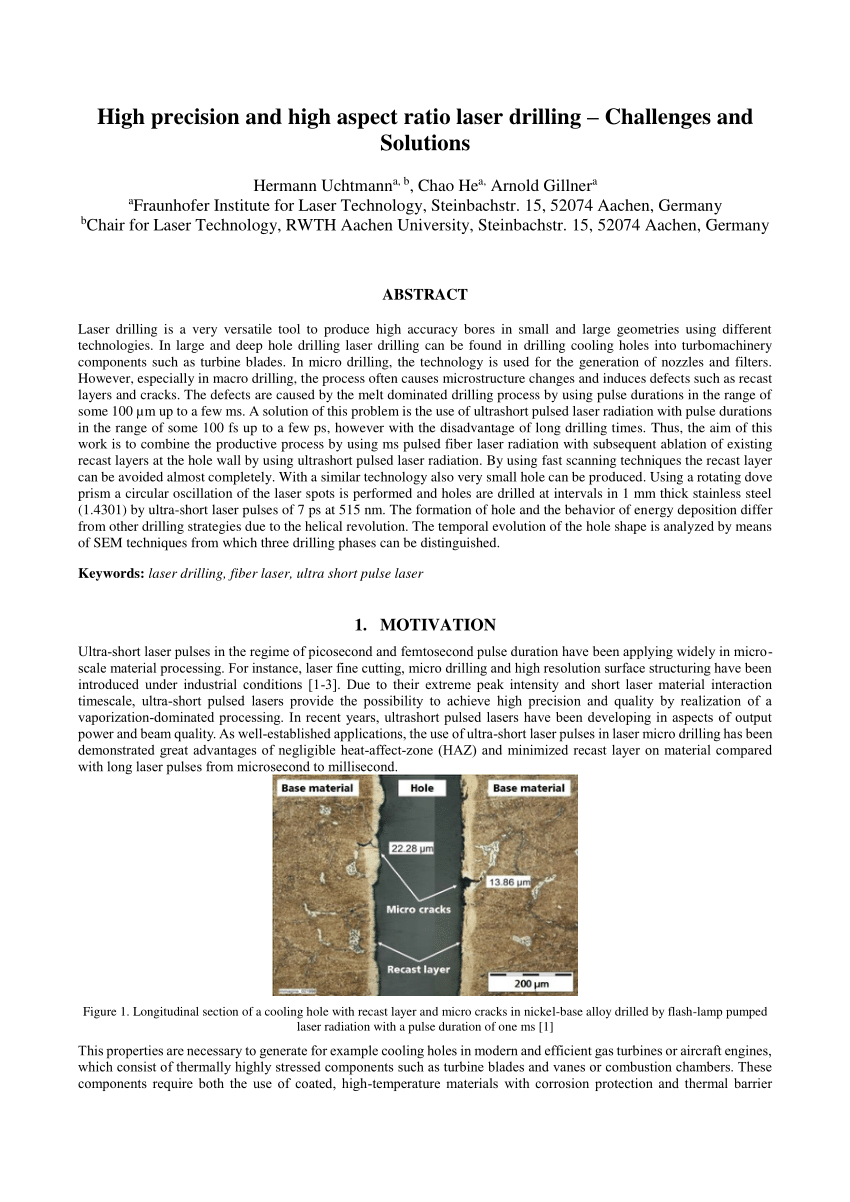

When considering laser drilling of glass and pcbs vs. Laser drilling is a non contact process that uses focused high energy density light to ablate material and drill holes in a wide variety of materials. Laser drilling and machining we specialize in laser micro drilling apertures orifices slits shapes pinholes and apodizers in a variety of materials dimensions and arrays. With laser drilling the impossible becomes possible.

Micro drilling is a laser micromachining process which creates extremely precise micro scale holes in material. In the case of drilling polymer materials especially polymer based medical devices where hole precision accuracy and quality are critical attributes the choice of machining technique is as important as the laser wavelength selection. Electrical discharge machining or edm laser drilling is much more precise.