Laser Edge Oxide Removal

Laser oxide removal can be used to remove those contaminants without introducing impurities in the base metal.

Laser edge oxide removal. Machine sits in the middle of four laser cutting machines. Even at the speed at which laser cutting machines operate harrison said the oxide removal equipment can keep up. Today the 107 5 by 59 1 by 60 2 in. Punched and laser cut parts often require high demands on the surface.

In some cases paint removal by sandblasting can damage the metal underneath. Using the laser s micron precision oxide can be removed in controlled layers and from predefined areas. Nitrogen prevents oxidation and leaves a clean edge that s ready for welding or painting. Laser oxide removal before welding and several other surface treatments metal surfaces must be clean and without oxides.

The problem is that the cost for nitrogen gas is generally five to six times greater than. If you are cutting via a co 2 laser with oxygen the edgeracer can remove any oxide layers along the cutting edge of the material. The 22 rb series for deburring edge rounding finishing and laser oxide removal. Furthermore a radius at the edge of the materials also improves paint adhesion.

The process creates a carbon oxide scale which appears as a shiny blue silver finish on and around the cut areas. The 22 series is the most compact dry operating machine for deburring edge rounding finishing and or laser oxide removal of various sheet metal parts. Another machine in the future. It is a cost effective solution that reduces cleaning times and.

Harrison added that typically one of the laser operators in the cell has time to send parts through the machine avoiding potential bottlenecks. This oxidation or scale left over from thermal cutting can cause problems for metal finishers and end customers alike. The ideal machine for companies with more. Oxide removal may involve hazardous chemicals specific to each material that needs to be removed.

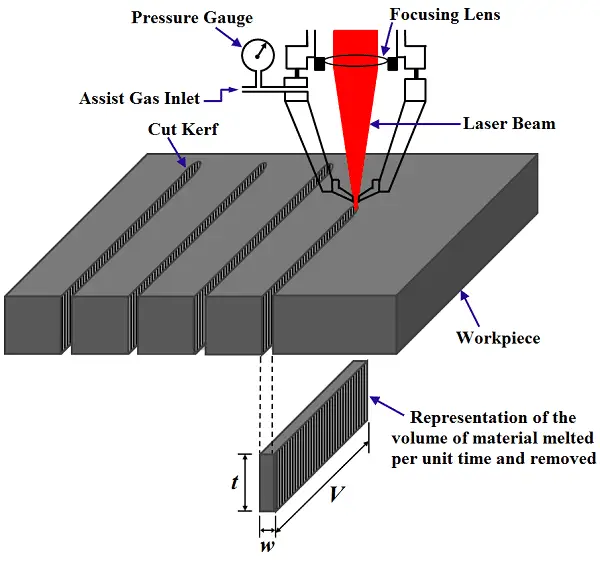

Truthfully some of the lasers are cutting with nitrogen most of the time but for those laser cut parts with an oxide layer on the edges the machine is more than able to keep up with the parts flow. Laser oxide removal as the use of thermal cutting processes in the metalworking industry has increased substantially the need to remove the oxidation produced by those processes has also increased. It takes about 20 or 30 seconds for a part to process through the machine. We could avoid the laser oxide problem completely by using nitrogen as an assist gas on our lasers instead.