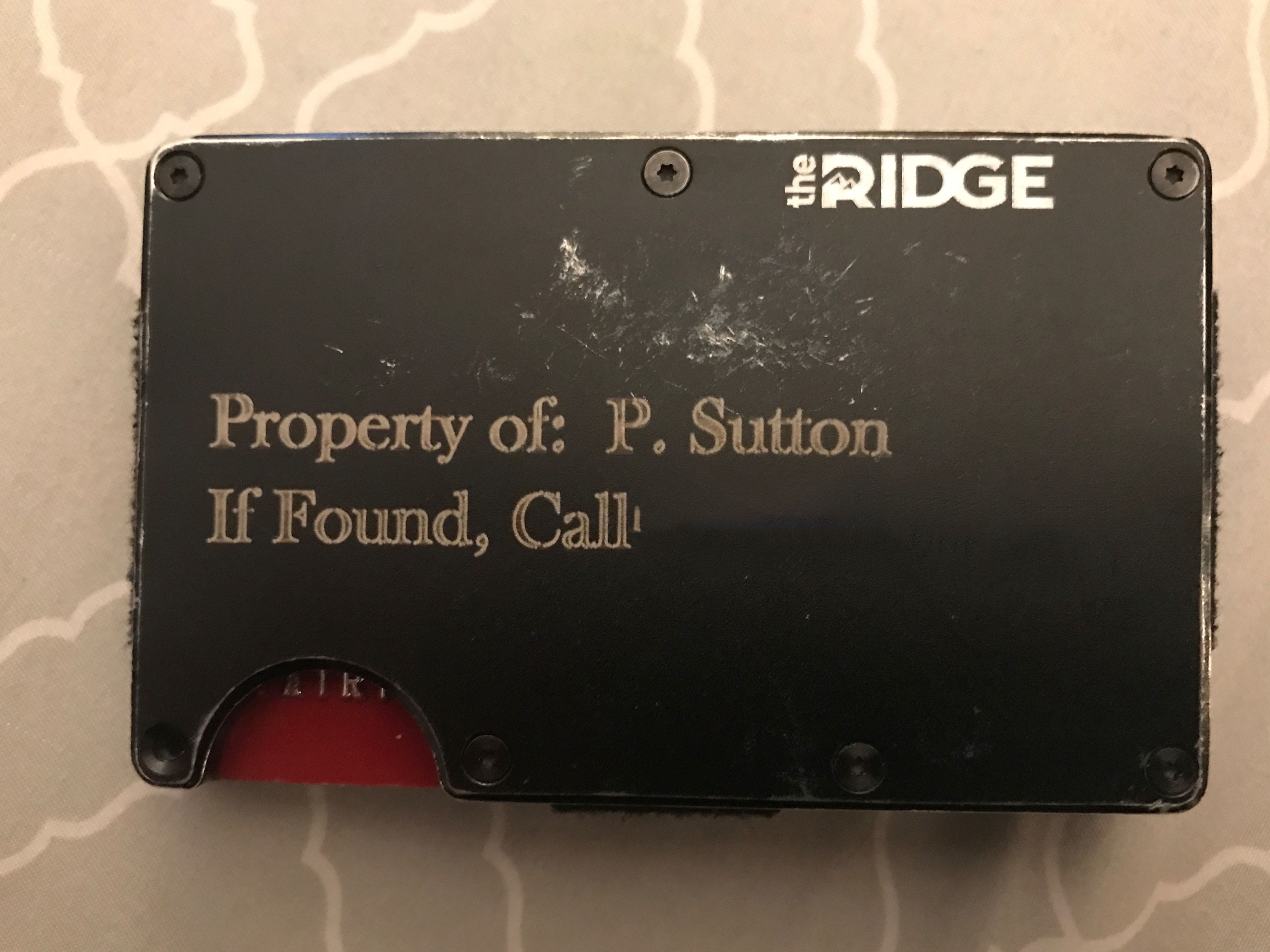

Laser Etching Painted Metal

Laser etching stands out when it comes to creating high contrast markings.

Laser etching painted metal. The advantage of metal marking with a co2 laser is that the mark is actually produced on top of the metal without removing material so there is no impact on the metal s tolerance or strength. The laser engraving machine is widely used for marking and labeling on painted metal products. Whereas laser engraving only creates black marks laser etching can be used to create both black and white marks. Although primarily sold as an aerosol co2 is also available as a liquid or powder.

Thermark and cermark a selection of top end products that are known to the market to achieve black marking. With the laser engraving machine you can engrave your designed graphic images words and logos on painted metal products which is commonly applied to electronics engraving mobile phone shell engraving logo engraving photo engraving and. Laser etching engraving etching and engraving are the main laser processes used to produce markings onto parts and products. The most common etchings and engravings are data matrix codes barcodes logos serial.

Another thing i want to try is covering the steel with paint or spray plastic and burning it off with the engraver then etching with vinegar and an adjustable power supply. Co2 metal marking this quick dry easy to use permanent metal laser ink provides the highest contrast ink in the industry. Should give a nice deep etch where the laser removed the masking. Engraving fabric but the laser burns through the material.

Laser marking paints and paint thinners oxidizers. It should also be noted that coated metals such as anodized aluminum or painted brass do not require pre treatment. If successful the void in the paint could then be used to electrochemically etch the holes in the sha. Negative laser etched metal.

Compatible with stainless steel titanium chromium nickel aluminum steel copper brass and the majority of crude metals. For this reason laser engraving is usually used in combination with laser etching to create high contrast engravings. The first step in avoiding burning fabric with a laser engraving cutting machine is to understand which fabrics can withstand the process and at what temperatures. Using a fiber laser system permanent markings can be etched and engraved onto most metals.

The only exception is stainless steel which requires laser annealing.