Laser Cladding By Powder Injection

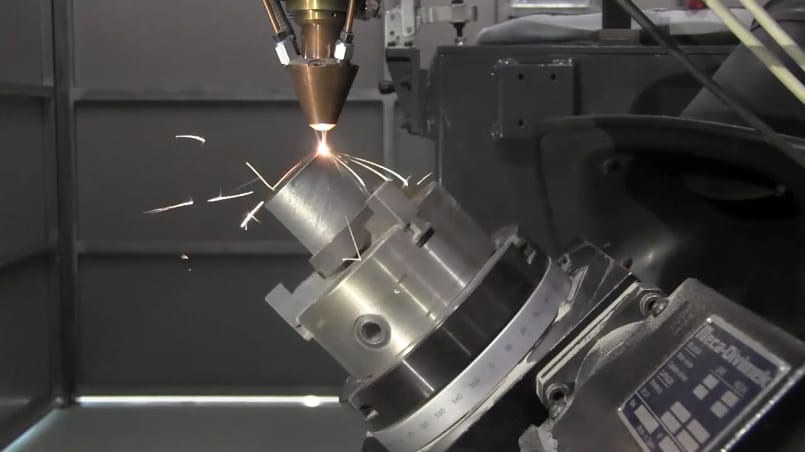

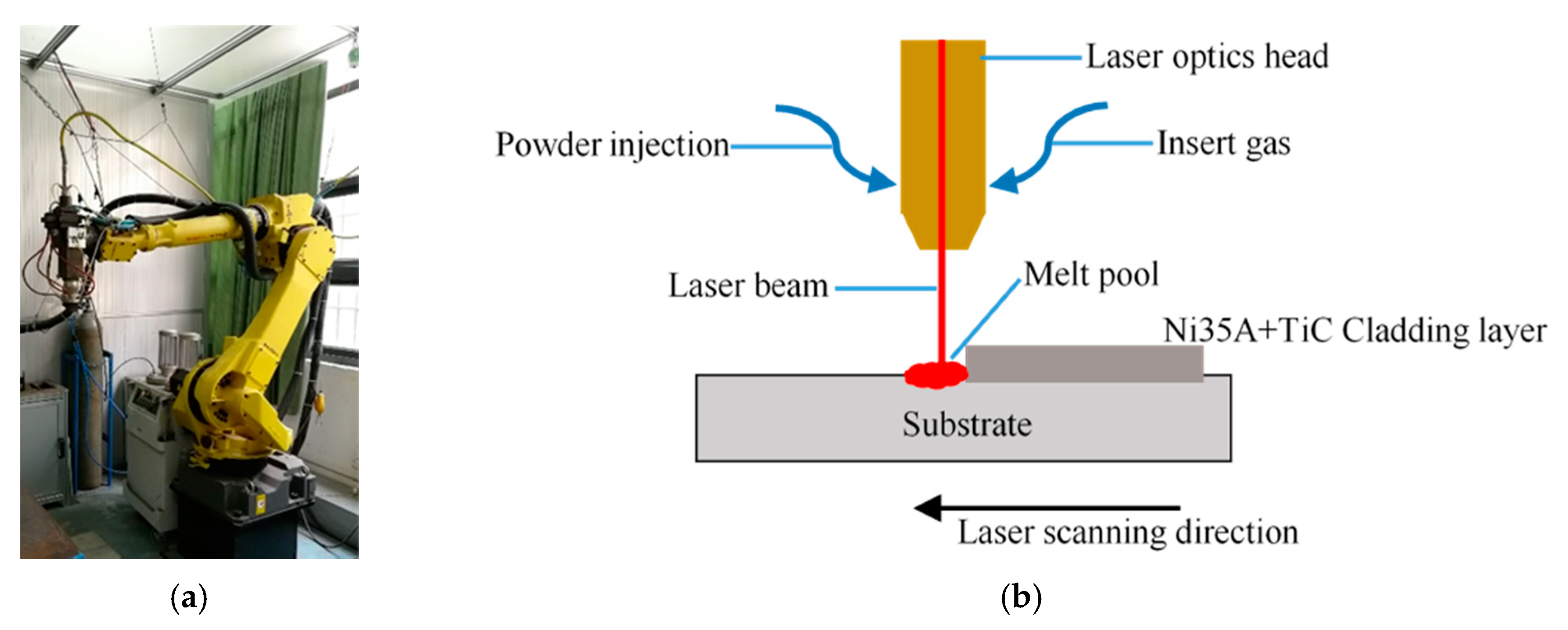

Many of the process parameters must be manually set such as laser power laser focal point substrate velocity powder injection rate etc and thus require the attention of a specialized technician to ensure proper results.

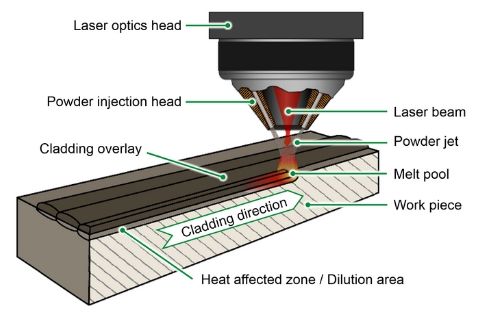

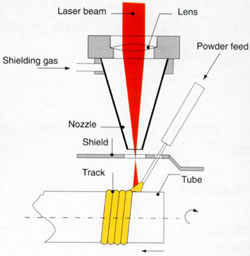

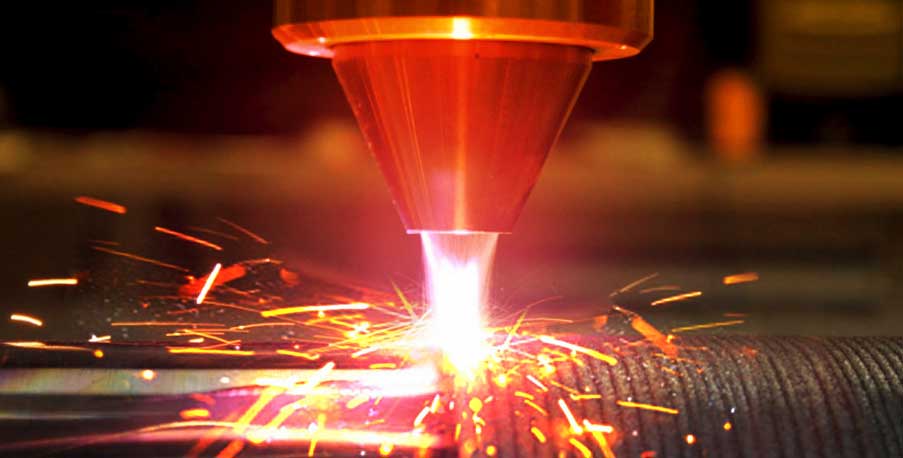

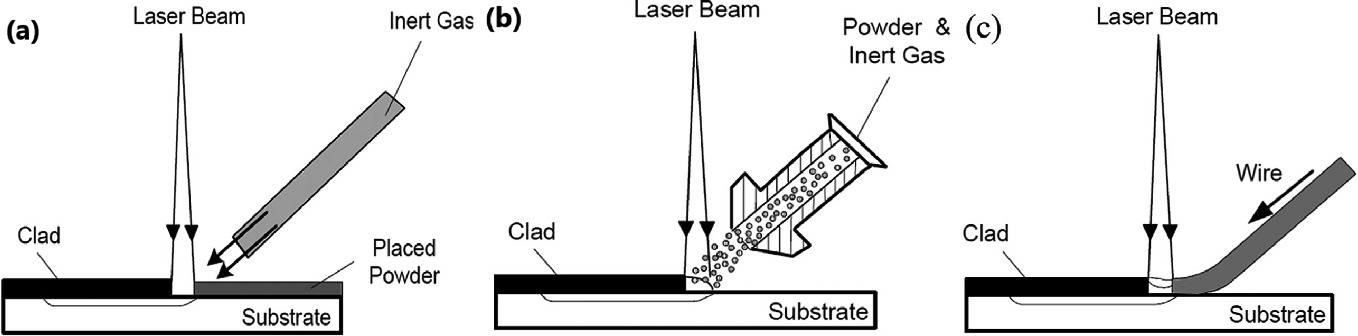

Laser cladding by powder injection. In this process a laser beam melts powder particles and a thin layer of the substrate to create a bulk layer on the substrate. The proposed model can predict clad geometry as a function of time and process parameters including beam velocity laser power powder jet geometry laser pulse shaping and material properties. To obtain a high quality resulting part a deep understanding of the underlying mechanisms is required. Laser cladding by powder injection is an advanced laser material processing technique which is used in manufacturing part repair coating and metallic rapid prototyping.

This article addresses a novel three dimensional transient finite element model of the laser cladding by powder injection process. Laser cladding is a fully automated additive process that uses a high power laser to create a weld pool. Using coaxial powder injection in combination with a lateral feed wire system improvements to the laser cladding process have been made. The capability to mix two or more types of powders and to control the feed rate of each powder flow makes laser cladding a flexible process for.

Optimization of the processing conditions article pdf available in journal de physique iv proceedings 01 c7 december 1991 with 65 reads. Laser cladding is one of the material additive manufacturing processes used to produce a metallurgically bonded deposition layer. It takes into account the melting of the powder in the liquid pool and the liquid gas free surface shape and position which must conform to the thermal field in order to obtain a self consistent. Filler material can be added via powder injection or hot wire offering a wide range of off the shelf and custom solutions.

A great deal of research is now being concentrated on developing automatic laser cladding machines. Laser cladding by powder injection. Laser cladding by a powder injection technique has been widely used in industrial applications such as rapid manufacturing parts repair surface coating and innovative alloy development. The model simulates the quasi steady temperature field for the longitudinal section of a clad track.

In the proposed method the interaction between powder and melt pool. A two dimensional 2 d finite element model is presented for laser cladding by powder injection. Laser cladding has the potential for very high deposition rates with dilution as low as 1 2.